2000w ka letsoho la laser welder

MOEKETSI MOTS'EANE

Selelekela

Ka nts'etsopele e tsoelang pele ea indasteri ea likoloi, litlhoko tsa katleho ea tlhahiso ea likoloi le boleng le tsona li ntse li eketseha butle-butle. Ts'ebetsong ea tlhahiso ea likoloi, ho cheselletsa 'mele ke mohato oa bohlokoa,' me mechini e ts'oarehang ka letsoho e bapala karolo ea bohlokoa ts'ebetsong ena. Sengoliloeng sena se tla fana ka kenyelletso e qaqileng mabapi le ts'ebeliso ea mochini o ts'oarellang ka letsoho ho cheselletsa 'mele.

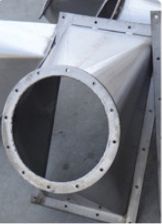

Kenyelletso ea Mochini oa Welding oa Handheld

Mechini ea ho tjheseletsa ka letsoho ke lisebelisoa tse sebetsang hantle le tse tenyetsehang tsa tjheseletsa tse sebelisoang haholo liindastering tse fapaneng joalo ka tlhahiso ea likoloi, tlhokomelo ea mochini le kaho. E na le melemo ea ho nkeha habonolo, ts'ebetso e bonolo, le tlhokomelo e bonolo, ka hona e bapala karolo e ke keng ea nkeloa sebaka ho tjheseletsa 'mele.

Tšebeliso ea mochini oa tjheseletsa o tšoaroang ka letsoho ho tjheseletsa 'mele oa koloi

Ho ntlafatsa katleho ea mosebetsi:Ho sebelisa mochini o ts'oarellang ka letsoho bakeng sa ho cheselletsa 'mele ho ka ntlafatsa haholo katleho ea mosebetsi. Ts'ebetso ea mechini e ts'oaroang ka letsoho e bonolo, 'me basebetsi ba nang le boiphihlelo ba ka etsa ts'ebetso e mengata ea ho cheselletsa ka nako e le ngoe, ba khutsufatsa haholo potoloho ea tlhahiso.

Boleng bo tsitsitseng:Mochini o ts'oaretsoeng ka letsoho o na le boleng bo tsitsitseng ba welding mme o ka fihlela litlhoko tse fapaneng tse thata tsa ts'ebetso. Ka taolo e nepahetseng ea hajoale le ea motlakase, botsitso le ts'epahalo ea lintlha tsa welding li ka netefatsoa.

Ho tenyetseha ho matla:Mochini o ts'oarellang ka letsoho o bonolo ho o jara mme o ka sebelisoa libakeng tse fapaneng tsa mosebetsi. Sena se lumella phetoho e feto-fetohang ea maemo a tjheseletsa le li-angles ho latela litlhoko tsa 'mele nakong ea ts'ebetso ea ho cheselletsa 'mele, ho ikamahanya le litlhoko tse fapaneng tse rarahaneng tsa welding.

Phokotso ea litšenyehelo:Ha ho bapisoa le mechini ea khale ea li-welding, mechini e ts'oarehang ka letsoho e na le litšenyehelo tse tlase tsa ho fumana le ho hlokomela. Ho sa le joalo, ka lebaka la ts'ebetso ea eona e sebetsang ea welding, e ka fokotsa mosebetsi le nako ea basebetsi, kahoo ea fokotsa litšenyehelo tsa basebetsi.

Qetello

Ka bokhutšoanyane, mechini e ts'oarellang ka letsoho e phetha karolo ea bohlokoa ho cheselletsa 'mele. Litšobotsi tsa eona tse sebetsang hantle, tse tenyetsehang, le tse tsitsitseng li e fa melemo e mengata ea ho ntlafatsa katleho ea tlhahiso, ho netefatsa boleng ba sehlahisoa, le ho fokotsa litšenyehelo tsa tlhahiso. Ka nts'etsopele e tsoelang pele ea thekenoloji, litebello tsa ts'ebeliso ea mechini e ts'oaroang ka letsoho e tla ba kholo le ho feta.

KOPO

e sebelisoang haholo liindastering tse tloaelehileng

E sebelisoa haholo lisebelisoa tsa kichineng, lemati le lifensetere, lifti ea litepisi, tšepe e sa hloekang, boto ea hardware. Lisebelisoa, limpho tsa mesebetsi ea matsoho, likoloi, sefofane le liindasteri tse ling

Guardrail

Kichine, kamore ea ho hlapela le lisebelisoa

Indasteri ea papatso

Sehlahisoa sa tšepe e sa hloekang

Indasteri ea likarolo tsa likoloi

Sekhabiso sa mabone

Kaho ea Mochini

MOEKETSI MOTS'EANE

| LASER MATLA | 1000W | 1500W | 2000W |

| Botebo ba ho qhibiliha (tšepe e sa hloekang, 1m/min) | 2.68 limilimithara | 3.59 limilimithara | 4.57 limilimithara |

| Botebo ba ho qhibiliha (tšepe ea carbon, 1m/min) | 2.06 limilimithara | 2.77 limilimithara | 3.59 limilimithara |

| Botebo ba ho qhibiliha (alloy ea aluminium, 1m/min) | 2mm | 3mm | 4mm |

| Ho fepa ka terata ka boiketsetso | φ0.8-1.2 terata ea ho tjheseletsa | φ0.8-1.6 terata tjheseletsa | φ0.8-1.2 terata ea ho tjheseletsa |

| Tšebeliso ea matla | ≤3kw | ≤4.5kw | ≤6kw |

| Mokhoa oa ho pholisa | pholiso ea metsi | pholiso ea metsi | pholiso ea metsi |

| Tlhokahalo ea matla | 220v | 220v kapa 380v | 380v |

| Tšireletso ea Argon kapa nitrogen (ea bareki) | 20 L/min | 20 L/min | 20 L/min |

| Boholo ba lisebelisoa | 0.6*1.1*1.1m | 0.6*1.1*1.1m | 0.6*1.1*1.1m |

| Boima ba lisebelisoa | ≈150kg | ≈170kg | ≈185kg |

Ho paka & ho Romela

Mochine o ne o tla kenngoa ka har'a kreiti e tiileng ea lepolanka bakeng sa likepe tsa machaba, tse loketseng lipalangoang tsa leoatle, tsa moea le tse potlakileng.