3000w laser welder

MOEKETSI MOTS'EANE

| LASER MATLA | 1000W | 1500W | 2000W |

| Botebo ba ho qhibiliha (tšepe e sa hloekang, 1m/min) | 2.68 limilimithara | 3.59 limilimithara | 4.57 limilimithara |

| Botebo ba ho qhibiliha (tšepe ea carbon, 1m/min) | 2.06 limilimithara | 2.77 limilimithara | 3.59 limilimithara |

| Botebo ba ho qhibiliha (alloy ea aluminium, 1m/min) | 2mm | 3mm | 4mm |

| Ho fepa ka terata ka boiketsetso | φ0.8-1.2 terata ea ho tjheseletsa | φ0.8-1.6 terata tjheseletsa | φ0.8-1.2 terata ea ho tjheseletsa |

| Tšebeliso ea matla | ≤3kw | ≤4.5kw | ≤6kw |

| Mokhoa oa ho pholisa | pholiso ea metsi | pholiso ea metsi | pholiso ea metsi |

| Tlhokahalo ea matla | 220v | 220v kapa 380v | 380v |

| Tšireletso ea Argon kapa nitrogen (ea bareki) | 20 L/min | 20 L/min | 20 L/min |

| Boholo ba lisebelisoa | 0.6*1.1*1.1m | 0.6*1.1*1.1m | 0.6*1.1*1.1m |

| Boima ba lisebelisoa | ≈150kg | ≈170kg | ≈185kg |

Ts'ebeliso ea mochini oa welding oa laser o ts'oaroang ka letsoho indastering ea lifofane

Selelekela

Indastering ea lifofane, mekhoa ea ho cheseletsa ea boleng bo holimo e bohlokoa bakeng sa ho netefatsa polokeho le ts'ebetso ea lifofane. Lilemong tsa morao tjena, mechine ea ho tjheseletsa laser ka letsoho butle-butle e ile ea tsebahala indastering ka lebaka la melemo ea eona e ikhethang. Sengoliloeng sena se tla fana ka kenyelletso e qaqileng mabapi le ts'ebeliso ea mochini o ts'oarellang oa laser ka letsoho indastering ea sefofane.

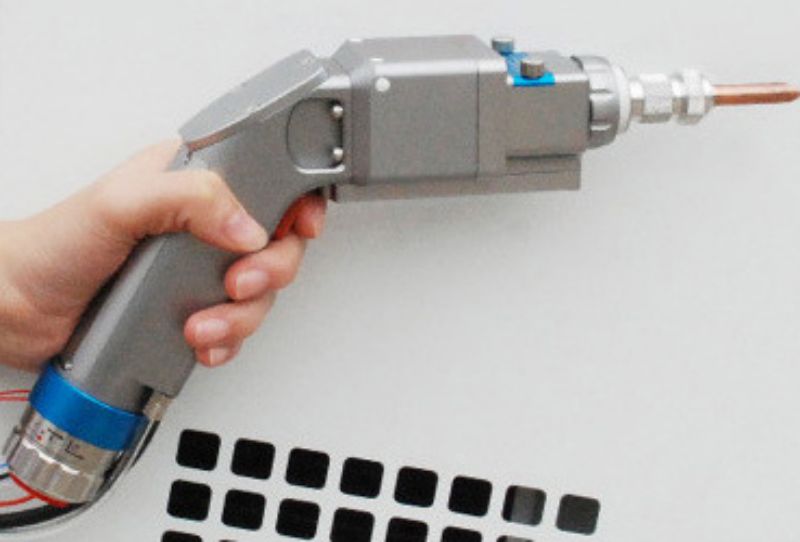

Kenyelletso ea Handheld Laser Welding Machine

Mochini o ts'oaroang ka letsoho oa laser welding ke sesebelisoa se tsoetseng pele sa laser welding se sebelisang mohloli o matla oa laser o fetisitsoeng ka likhoele tsa optical, 'me o lebisitsoe ka nepo le ho lokisoa ke sistimi e tsoetseng pele ea taolo. Mochini o ts'oarehang oa laser oa letsoho o na le melemo ea ts'ebetso e bonolo, ho ikamahanya le maemo ho matla, lebelo le potlakileng la welding, le boleng bo phahameng ba welding.

Kopo indastering ea lifofane

Welding ea boleng bo holimo:Mochini o ts'oarehang oa laser o ka fihlela sepheo se nepahetseng le ho lokisoa, ka hona ho netefatsa boleng le ho nepahala ha welding. Lefapheng la lifofane, taolo ea boleng ba tjheseletsa e bohlokoa haholo, mme ts'ebeliso ea mochini o ts'oarellang oa laser o ka ntlafatsa boleng ba welding haholo.

Katleho:Mochini oa welding oa laser o tšoarang letsoho o ka phethela ts'ebetso ea boleng bo holimo ka nako e khuts'oane, o ntlafatsa haholo ts'ebetso ea tlhahiso. Sena se bohlokoa haholo indastering ea sepakapaka, kaha se hloka ts'ebetso ea palo e kholo ea likarolo le likarolo, 'me mekhoa e metle ea tlhahiso e bohlokoa bakeng sa ho netefatsa boleng le tsoelo-pele ea tlhahiso ea lifofane.

Ho feto-fetoha ha maemo:Mechini ea welding ea letsoho ea laser e na le maemo a holimo ebile e khona ho sebetsana le litlhoko tse fapaneng tse rarahaneng tsa welding. Ebang ke tjheseletsa matheba, butt welding, kapa fillet welding, metjhini e ts'oarehang ea laser e ka sebetsana le eona habonolo. Ho tenyetseha hona ho e fa melemo e meholo ea ho sebetsana le likarolo tsa libopeho le boholo bo fapaneng.

Ho ikamahanya le maemo:Mochini o ts'oarehang oa laser o ka ikamahanya le lisebelisoa tse fapaneng tsa likarolo, ho kenyelletsa le tšepe, e seng tšepe, joalo-joalo. Ho ikamahanya le maemo ho etsa hore e be le karolo ea bohlokoa ho sebetsanang le mefuta e sa tšoaneng ea lifofane.

Botsoalle ba tikoloho:Mochini oa welding oa laser o tšoaroang ka letsoho ha o hlahise lintho tse kotsi nakong ea ts'ebetso ea welding mme o fihlela litlhoko tsa tikoloho. Lefapheng la lifofane, botsoalle ba tikoloho ke taba ea bohlokoa haholo, kahoo ho sebelisoa ha mechine ea ho tjheseletsa laser ka letsoho ho ka thusa ho fokotsa tšusumetso tikolohong.

Qetello

Melemo ea mechine ea ho tjheseletsa laser ka letsoho e etsa hore e sebetse haholo indastering ea lifofane. E ke ke ea ntlafatsa ts'ebetso ea tlhahiso feela, empa hape e sebetsana ka katleho le litlhoko tse fapaneng tse rarahaneng tsa welding. Ka nako e ts'oanang, botsoalle ba eona ba tikoloho le litšobotsi tsa ho boloka mosebetsi le tsona li etsa hore e be khetho e nepahetseng bakeng sa indasteri ea lifofane. Ka ntshetsopele e tswelang pele ya thekenoloji, tshebetso le mesebetsi ya metjhini e tjheseletsang laser ka letsoho le yona e tla ntlafatswa le ho ntlafatswa le ho feta, mme ditshebediso tsa bona indastering ya difofane le tsona di tla ba tse pharalletseng le tse tebileng.

Ho ntlafatsa boleng ba tjheseletsa Mefuta e tsheletseng ya ho tjheseletsa

E ka phethela litlhoko tsa welding tse ke keng tsa phethoa ke li-welders tse tloaelehileng, 'me weld e tiile ebile e ntle,Ha ho tjheseletsa slag, ha ho bonolo ho deformation, e ntšo

Spot welding:sebaka se senyenyane, matla a matla, mokhoa oa ho cheselletsa letheba o ka sebelisoa ha thepa e na le litlhoko tsa ho kenella ha welding;

Mohala o otlolohileng:bophara bo ka fetoloa, thepa e na le ho kenella, ho tjheseletsa ka splicing, wire feeding welding, Positive fillet welding e ka sebelisa mokhoa oa ho tjheseletsa oa linear;

Mofuta oa "O":bophara bo feto-fetohang, kabo e tšoanang ea matla a matla; Maqhubu a phahameng ha ho cheselletsa letlapa "O" ho ka sebelisoa;

Habeli "O":bophara bo feto-fetohang, fokotsa letheba le khanyang, le loketseng bakeng sa ho cheselletsa li-angles tse fapaneng;

Triangle:Bophara bo ka fetoloa ho fokotsa sebaka sa leseli ha matla a mahlakoreng a mararo a lekana. Bohareng le mahlakoreng a mabeli a poleiti a futhumetse ka ho feletseng;

"8" lentsoe:tsoela pele ho eketsa leseli letheba motheong oa khutlo-tharo, e le hore poleiti e chese hangata, e kholo.

"8" paterone e ka sebelisoa bakeng sa tjheseletsa bophara.

Ho paka & ho Romela

Mochine o ne o tla kenngoa ka har'a kreiti e tiileng ea lepolanka bakeng sa likepe tsa machaba, tse loketseng lipalangoang tsa leoatle, tsa moea le tse potlakileng.