Handheld Laser Welder bakeng sa Metal

MOEKETSI MOTS'EANE

Selelekela

Ka nts'etsopele ea theknoloji, theknoloji ea welding ea laser, e le mokhoa o sebetsang hantle le oa boleng bo holimo, o sebelisitsoe haholo indastering ea kaho ea likepe. Har'a bona, mechini e ts'oarehang ea laser e ts'oaroang ka letsoho butle-butle e nka boemo bo ka sehloohong indastering ka lebaka la ho tenyetseha le katleho ea eona. Sengoliloeng sena se tla fana ka kenyelletso e qaqileng mabapi le ts'ebeliso ea mochini o ts'oarellang oa laser ka letsoho indastering ea kaho ea likepe.

Kenyelletso ea Handheld Laser Welding Machine

Mochini o ts'oarehang oa laser o ts'oaretsoeng ka letsoho ke lisebelisoa tse phahameng tse nepahetseng, tse matla haholo tse nang le melemo ea ts'ebetso e bonolo, ts'ebetso e matla, lebelo le potlakileng la welding, sebaka se senyenyane se amehileng ke mocheso, le boleng bo phahameng ba weld. E fihlella welding e sebetsang hantle le ea boleng bo holimo ka ho khantša bokaholimo ba thepa ea ho haha likepe ka maballo a matla a matla a laser.

Sebaka sa kopo

Hull structure welding: Sebopeho sa Hull ke karolo ea bohlokoa ea tlhahiso ea likepe, 'me mekhoa ea khale ea ho tjheseletsa e thata ho fihlela litlhoko tsa tlhahiso ea likepe tsa sejoale-joale ka lebaka la litaba tse kang ts'ebetso e tlase le boleng bo tlase ba weld. Ho hlaha ha mechine ea ho tjheseletsa laser ka letsoho ho ntlafalitse haholo ts'ebetso ea ho tjheseletsa le boleng ba mehaho ea likepe ka lebaka la melemo ea bona ea ho nepahala le lebelo le phahameng.

Deck le cabin welding: Deck le cabin ke likarolo tsa bohlokoa tsa sekepe, tse hlokang boleng bo phahameng haholo ba ho cheselletsa. Mochini oa welding oa laser o tšoaroang ka letsoho o ka fihlela matla a phahameng le ho tiisa ho tiisa, ho fihlela litlhoko tsa tjheseletsa tsa li-decks le li-cabins.

Welding ea liphaephe le lisebelisoa: Boleng ba tjheseletso ba lipeipi le lisebelisoa bo amana ka kotloloho le polokeho le ts'ebetso ea likepe. Mochini o ts'oaretsoeng ka letsoho oa laser tjheseletsa o sebetsa hantle haholo ho tjheseletsa liphaephe le lisebelisoa, o nolofalletsa ho cheselletsa ka nepo le ka potlako.

E loketse mefuta e fapaneng ea lits'ebetso tsa welding

Lebelo le potlakileng. ha ho botsho. ha ho na deformation

Laser, chiller, welding wire wire feeder lintlafatso ka nako ea nnete

E bonolo ebile e bonolo ho ithuta u se ke ua khetha batho ho fokotsa litšenyehelo tsa basebetsi

Mocheso o habeli le taolo e habeli lebelo le pholileng lerōle le thibelo ea condensation

Ts'ehetsa nts'etsopele ea bobeli Ts'ehetso ea liroboto tsa ho emisa

MOEKETSI MOTS'EANE

| Lebitso la Sesebelisoa | Mochini oa Welding oa Laser o tšoaroang ka letsoho | Matla a Laser | 1000w-3000w |

| Sehlahisoa sa Metsi | Hanli | Kopo ea Metsi ka Chiller ea Metsi | Metsi a hloekisitsoeng / metsi a hloekileng |

| Khase e Sireletsang | N2/AR | Operating voltage | AC220 |

| Wire feeding | Ka ho iketsa | Mongobo o teng | Ka tlase ho 70% ntle le condensation |

| Laser wavelength | 1070 土10nm | Omocheso oa perating | -10C kapa 45C |

| Lekhalokopo | <0.5mm | Mbotebo ba ho qhibiliha | 8mm |

| Ho ikemisetsa le ho lokisa | Lehlaseli la infrared | Gjoalo ka tšebeliso | 20ml/min |

| Automatic welding port e tšehetsa | ho joalo | Lisebaka sa marang-rang | 0 ho isa ho 5 mm |

| Bolelele ba fiber | maemo a 10m | Pulse width | 0.3mm ~ 10mm |

| Bokhoni ba ho cheselletsa | 0.5-4 limilimithara | Tiisetso | 1 selemo |

Melemo le Liphello

Ho ntlafatsa ts'ebetso ea welding:Ha ho bapisoa le mekhoa ea khale ea ho tjheseletsa, metjhini e ts'oaroang ka letsoho ea laser e na le lebelo le holimo la ho cheselletsa le ho sebetsa hantle, e khutsufatsang potoloho ea kaho ea sekepe haholo.

Ho ntlafatsa boleng ba weld:Ka lebaka la mocheso o monyenyane o amehileng ka laser welding, microstructure ea weld e teteaneng haholoanyane, e leng ho ntlafatsang boleng ba weld. Ka nako e ts'oanang, taolo e nepahetseng ea mechine ea ho tjheseletsa laser e tšoaroang ka letsoho e boetse e qoba liphoso tse ka 'nang tsa hlaha ho tloha mekhoeng e tloaelehileng ea ho cheselletsa.

Ho fokotsa litšenyehelo tsa tlhahiso:Ts'ebetso e phahameng ea deposition ea laser welding e ntlafatsa ts'ebeliso ea thepa, e fokotsa tšebeliso ea thepa le tlhahiso ea litšila, hape e fokotsa litšenyehelo tsa tlhahiso.

Ho ntlafatsa polokeho ea tlhahiso:Mekhoa ea khale ea ho tjheseletsa e ka hlahisa dintho tse kotsi tse kang mabone a arc le mosi nakong ya tshebetso, e leng se bakang tshokelo ho bophelo ba basebetsi. Nakong ea ts'ebetso ea welding ea laser, ha ho na moloko oa leseli la arc, mosi, joalo-joalo, o ntlafatsang polokeho ea tlhahiso.

Maikutlo

Ka nts'etsopele e tsoelang pele ea theknoloji, ts'ebetso le ts'ebetso ea mochini oa welding oa laser o tla ntlafatsoa le ho feta. Tšebeliso ea eona indastering ea kaho ea likepe le eona e tla ba e pharaletseng haholoanyane, e sa felle feela ho cheselletsa meaho ea li-hull, li-decks le li-cabins, liphaephe le lisebelisoa, empa hape e tla atolosoa ho ea libakeng tse ling tse kang mokhabiso oa ka hare ho likepe le tlhahiso ea likarolo. Ho sa le joalo, ka nts'etsopele ea tlhahiso e tala le tlhahiso e bohlale, ts'ebeliso ea mochini o ts'oarellang oa laser o ts'oaroang ka letsoho ha ho etsoa likepe le ona o tla boloka tikoloho, o sebetsa hantle, hape o bohlale.

Qetello

Tšebeliso ea mechine ea laser welding e nang le letsoho ke ts'ebetso e kholo ea theknoloji indastering ea kaho ea likepe, e fanang ka tšehetso e matla bakeng sa kaho ea likepe ka melemo ea eona ea ts'ebetso e phahameng le boleng. Ka tsoelo-pele e tsoelang pele ea thekenoloji, re na le lebaka la ho lumela hore mechine ea ho roala ka letsoho ea laser e tla phetha karolo ea bohlokoa ho feta indasteri ea kaho ea likepe e tlang.

Tanka e tiisitsoeng ea tšepe e sa hloekang

Li-Racks tsa polokelo

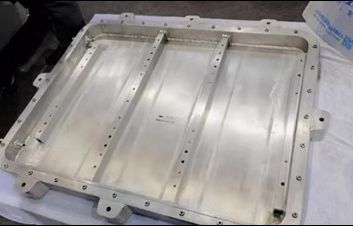

Khetla ea profil ea aluminium bakeng sa likoloi tse ncha tsa matla

Kitchen le bathroom customization

Lisebelisoa tsa metsi tse hloekisitsoeng tsa bongaka

Ho paka & ho Romela

Mochine o ne o tla kenngoa ka har'a kreiti e tiileng ea lepolanka bakeng sa likepe tsa machaba, tse loketseng lipalangoang tsa leoatle, tsa moea le tse potlakileng.