Mochini oa Welding oa Laser o tšoaroang ka letsoho

Tlhaloso

Mochini oa welding oa Mini Type o tšoarang letsoho oa Fiber laser o kopanya litšoaneleho tsa mantlha tsa sesebelisoa se nkehang habonolo le ts'ebetso e sa thekeseleng.

FTW-SL-1000/1500/2000 Mini handheld laser welding machine o amohela moloko oa morao-rao oa fiber laser 'me o na le OSPRI handheld laser welding head, e tlatsang lekhalo la ho tjheseletsa ka letsoho indastering ea lisebelisoa tsa laser. Ka melemo ea lebelo le potlakileng la ho cheselletsa 'me ha ho na lintho tse ka sebelisoang, e ka nkela tjheseletsa ea khale ea argon Arc(TIG), welding ea motlakase le lits'ebetso tse ling ha ho tjheseletsa lipoleiti tse tšesaane tse se nang tšepe, lipoleiti tsa tšepe, lipoleiti tsa masenke le lisebelisoa tse ling tsa tšepe. Laser e tšoaroang ka letsoho.

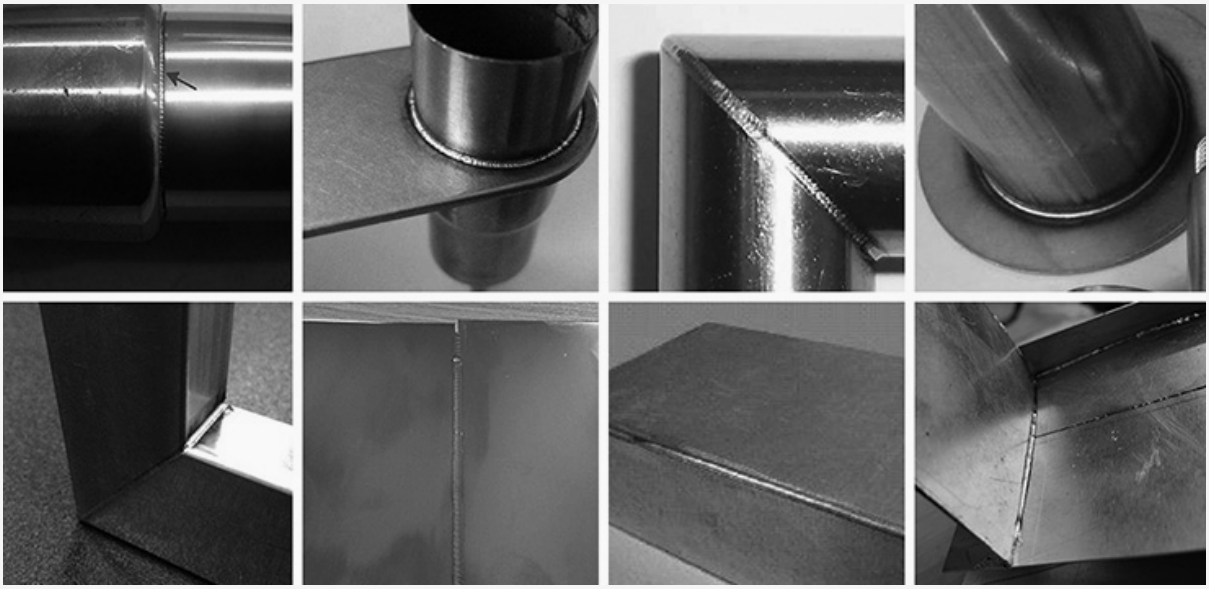

mochini oa tjheseletsa o ka sebelisoa haholo lits'ebetsong tse rarahaneng le tse sa tloaelehang tsa ho tjheseletsa ka kichineng le ka kamoreng ea ho hlapela, lifti ea litepisi, sethala, ontong, lemati la tšepe e sa hloekang le letamo la lifensetere, lebokose la kabo, ntlo ea tšepe e sa hloekang le liindasteri tse ling.

Tekheniki Parameter

| Mohlala | FTW-SL-1000 | FTW-SL-1500 | FTW-SL-2000 |

| Matla a Laser | 1000W | 1500W | 2000W |

| Mohloli oa Laser | Raycus/Max/IPG/ SUNLITE | Raycus/Max/IPG/ SUNLITE | Raycus/Max/IPG/ SUNLITE |

| Hlooho ea Laser | OSPRI | OSPRI | OSPRI |

| Bolelele ba Fiber Wire | 5/10 Limithara | 5/10 Limithara | 5/10 Limithara |

| Laser Wavelength | 1070nm | 1070nm | 1070nm |

| Mokhoa oa ho sebetsa | Tsoelo-pele/ Fetola | Tsoelo-pele/ Fetola | Tsoelo-pele/ Fetola |

| Sehlahisoa sa Metsi | Hanli/S&A | Hanli/S&A | Hanli/S&A |

| Spot Adjusting Range | 0.1-3 limilimithara | 0.1-3 limilimithara | 0.1-3 limilimithara |

| Pheta Precision | ± 0.01 limilimithara | ± 0.01 limilimithara | ± 0.01 limilimithara |

| Boholo ba Kabinete | 744*941*1030mm | 744*941*1030mm | 750*1260*1110mm |

| Boima ba Mochini | Hoo e ka bang 200KG | Hoo e ka bang 200KG | Hoo e ka bang 220KG |

| Palo ea li-volts | 110V/220V/380V | 110V/220V/380V | 110V/220V/380V |

Litlhahiso tsa Mochini

1. Mabapi le Bolelele ba Cable ea Fiber

Hangata bolelele bo tloaelehileng ke 10m, haeba u na le litlhoko tse ling, re tšehetsa ho khutsufatsa kapa ho lelefatsa.

2. Khase e thusang: nitrogen kapa argon

Haeba ho hlokahala hore ho be le phello e tšoeu le e khanyang, ho hlokahala naetrojene kapa argon.

Haeba ho sa hlokahale bakeng sa bokaholimo ba tjheseletsa, eketsa moea o hatelitsoeng oa Dryer, moea o lokile.

3. Mabapi le wire feeder

Ke tlhophiso e tloaelehileng ea mochini, re tla u romella hammoho le mochini kaofela.

4. Tiisetso ea mochine

hangata lilemo tse 2, re na le sehlopha sa litsebi ka mor'a thekiso, lihora tse 24 inthaneteng.

Sesebelisoa sa Mochini

Fiber Laser tjheseletsa mochine o loketse bakeng sa ho tjheseletsa khauta, silevera, titanium, nickel, tin, koporo, aluminium le tšepe tse ling le lisebelisoa tsa bona tsa motsoako. E ka finyella ho tjheseletsa ho nepahetseng ho tshwanang pakeng tsa dimetale le dimetale tse sa tshwaneng. E 'nile ea sebelisoa haholo sebakeng sa lifofane, kaho ea likepe le lisebelisoa. Lihlahisoa tsa mechini le tsa motlakase, likoloi le liindasteri tse ling.

Lintlha tsa Mochini

RAYCUS MAX SUNLITE Fiber Laser Mohloli oa Khetho

Ha ho bapisoa le lihlahisoa tse tšoanang, RAYCUS MAX SUNLITE Fiber laser Source e na le matla a phahameng a ho fetola photoelectric perfor-mance, stablebeam haholoanyane, le matla a matla a ho thibela ho bonahatsa.

Matla a laser a boikhethelo a tloha ho li-watts tse 1000 ho isa ho tse 2000. Re na le R&D e sebetsang hantle le e hloahloa le sehlopha sa tlhahiso, e leng boleng bo holimo China. Li-laser li na le phetoho e phahameng ea electro-optical.

OSPRI (QILIN) Fiber Laser Welding Head

1. Swing tjheseletsa hlooho

Ts'ebetso eo hlooho ea khoheli ea setso e ke keng ea e phethela, hlooho ea swing welding e hloka feela ho sebelisa 70% ea matla, e ka bolokang litšenyehelo tsa laser; Ho phaella moo, mokhoa oa ho tjheseletsa oa swing o amoheloa, bophara ba motsoako oa ho tjheseletsa bo ka fetoha, 'me ho mamellana ha phoso ho matla, e leng se etsang hore ho be le mefokolo e nyenyane ea motsoako oa laser welding. Palo ea mamello le bophara ba welding ea likarolo tse sebetsitsoeng lia atolosoa, 'me ho fumanoa phello e ntle ea ho etsa welding.

2. 360 degree micro welding

Ka mor'a hore lebone la laser le tsepame, ntlha e ka behoa ka nepo 'me ea sebelisoa bakeng sa ho tjheseletsa ka lihlopha tsa lisebelisoa tse nyenyane le tse nyenyane ho finyella tlhahiso ea bongata.

3. Handheld laser tjheseletsa hlooho Nozzles

Ha re na le faeba handheld laser welder le sebaka sa tjheseletsa nozzle ka seha nozzle, re ka e bitsa handheld faeba laser tjheseletsa le ho itšeha mochini. Na ha se lebitso le letle!

E ka nka fiber ea optical ho tloha ho laser fiber 'me ea e bokella sebakeng se senyenyane ho hlahisa laser e matla haholo bakeng sa morero oa ho itšeha. Leha ho le joalo, ka kopo hlokomela hore ha e khone ho khaola thepa e teteaneng haholo.

Boleng bo holimo ba Ospri Wobble Welding Head

1. The wobble tjheseletsa kopanelo e ikemetseng e ntshetswa pele amohela mokgwa wa swing welding.

2. Bophara ba sebaka se khanyang bo ka fetoloa.

3. The tjheseletsa phoso mamello e matla, e leng se etsa bakeng sa mosing oa tse nyenyane laser tjheseletsa letheba, atolosa ho mamella mefuta e fapaneng le tjheseletsa bophara ba likarolo sebetswa, 'me o fumana molemo tjheseletsa theha.

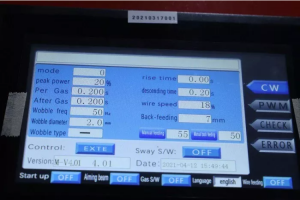

Sistimi ea taolo ea OSPRI

Sistimi ea taolo ea OSPRI e etselitsoe ka ho khetheha ho tsamaisana le hlooho ea eona ea OSPRI laser welding. E tla le mefuta e 'maloa ea mofuta, mohlala oa CW, mohlala oa PWM oa Arc.

Skrine sa taolo ka ho toba se beha liparamente tsa terata.

Sistimi e hlokomela boemo ba ts'ebetso ka nako ea nnete, e beha leihlo le ho bokella boemo ba ts'ebetso ea laser, chiller, le control board.

Ts'ehetsa litsamaiso tsa lipuo tsa Sechaena, Senyesemane, Sekorea, Sejapane, Serussia, Sefora, Sepanish, Seisraele.

HANLI Water Chiller FOR LASER WELDER (KGETHO)

Hanli Water Chiller E entsoe ka ho khetheha bakeng sa lisebelisoa tsa laser fiber, phello e ntle ea ho pholisa. Ts'ebetso e tsitsitseng le e ka tšeptjoang, tekanyo e tlaase ea ho hlōleha, matla a matla.

Mofani oa terata o itekanetseng

Mohaho oa ho fepa oa li-dual drive terata o etsa hore phepelo ea terata e be boreleli le ho ba matla ntle le ho jama ka terata; Moralo oa chassis o koetsoeng, o nang le molamu o phahamisitsoeng le lebili la bokahohleng; Taolo ea ho fepa ka terata, skrini sa LED se bonts'a lebelo la ho fepa ka nako ea nnete; Kotopo ea taolo ea lebelo le holimo, le lebelo le nepahetseng la ho fepa ka terata.

1000W le 1500W tšehetso 0.8mm 1.0mm 1.2mm terata, 2000W tshehetso 0.8mm ho 1.6mm.

Lebelo la ho romella le ho khutla ka mohala li fetotsoe ka phanele ea ho ama.

Haeba tse peli weld tšepe lekhalo le fetang 0.2mm hore hloka filler terata.

Molemo oa Sehlahisoa

TŠEBELETSO EA FIBER LASER Vs. TIG TIG Welding e tloaelehileng

FIBER LASER CHESE

Ts'ebetso e bonolo, e fokotsa haholo litšenyehelo tsa basebetsi.Mahlaseli a sa tobang a fokola. Lebelo le lebelo le sebetsang hantle ke makhetlo a 3-8 a argon arc welding. Matla a tsitsitseng le tšusumetso e fokolang ea ho senyeha ha mocheso. Seam se setle sa welding, letamo le qhibilihileng le tebileng, matla a phahameng. Lisebelisoa tse tšesaane haholo li ka tšeloa, tse kang tšepe e sa hloekang ea 0.05mm. Both autogenous welding le additive welding li lokile.

TIG TIG Welding e tloaelehileng

Litlhoko tsa botsebi le tsa tekheniki li phahame, tse lebisang ho theko e phahameng ea basebetsi. Kotsi e kholo 'meleng oa motho. E liehang ebile e sa sebetse. Tšusumetso ea mocheso e kholo, e lebisang ho deformation e kholo. Seam se cheselletsang se mahoashe ebile ha se tloaelehe. E hloka ho sila le ho belisoa. Ha e khone ho cheselletsa lisebelisoa tse tšesaane haholo. Consumables welding terata ea hlokahala. Ho bonolo ho kena.

Welding Material Parameterbakeng sa litšupiso tsa hau, lisebelisoa tse fapaneng, liparamente tse fapaneng tsa welding, tse lekantsoeng ke karolo, li bonts'a karolo ka kotloloho.

Haeba u batla ho tseba haholoanyane ka paramente, ka kopo ikopanye le rona ka kotloloho, lihora tse 24 inthaneteng.