Laser Welding Machine bakeng sa lisebelisoa tsa bongaka

Litšobotsi tsa mochini:

Tšebeliso ea Mochini oa Welding oa Laser ho Indasteri ea Lisebelisoa tsa Bongaka

Mechini ea welding ea laser, joalo ka theknoloji e tsoetseng pele ea ho tjheseletsa, e sebelisitsoe haholo indastering ea lisebelisoa tsa bongaka. Se latelang ke selelekela se qaqileng mabapi le tšebeliso ea mochini oa welding oa laser indastering ea lisebelisoa tsa bongaka.

Ho cheselletsa lisebelisoa tsa ho buoa

Mechini ea tjheseletsa ea laser e phetha karolo ea bohlokoa tlhahisong ea lisebelisoa tsa ho buoa. Lisebelisoa tsa ho buoa li hloka ho ba le ho nepahala ho phahameng le ho tšepahala ho netefatsa polokeho le katleho nakong ea ts'ebetso ea ho buuoa. Mechini ea tjheseletsa ea Laser e ka fihlella welding e nepahetseng haholo, ho netefatsa boleng le botsitso ba ntlha e 'ngoe le e' ngoe ea tjheseletsa, le ho qoba mathata a kang deformation le mapetsong a bakoang ke mekhoa ea khale ea ho tjheseletsa. Ka nako e ts'oanang, mechini ea welding ea laser le eona e ka fihlela tjheseletsa ea mefuta e fapaneng ea lisebelisoa tsa ho buoa, ho fihlela litlhoko tsa liopereishene tse fapaneng.

Ho tjheseletsa thepa ya meno

Ho etsoa ha lisebelisoa tsa meno ho hloka tsebo e nepahetseng le lisebelisoa tsa boleng bo phahameng ho netefatsa tšireletso ea mokuli le liphello tsa phekolo. Mechini ea welding ea Laser e ka fihlela welding e nepahetseng haholo ea lisebelisoa tsa meno, ho qoba mathata a kang deformation le liphoso tse bakoang ke mekhoa ea khale ea ho cheselletsa. Ka nako e tšoanang, laser tjheseletsa mechine e ka boela finyella tjheseletsa mefuta e fapaneng ya liletsa meno, ho finyella litlhoko tsa mefuta e fapaneng ya kalafo meno.

Welding ea limela tsa masapo

Li-implants tsa masapo ke lisebelisoa tsa bongaka tse sebelisetsoang ho phekola maloetse a kang fractures, a hlokang ho tšepahala ho phahameng le botsitso. Laser tjheseletsa mechine ka finyella boleng bo phahameng tjheseletsa dimela masapo, ho qoba mathata a kang deformation le mapetsong a bakoang ke mekhoa tjheseletsa setso. Ka nako e ts'oanang, mochine oa welding oa laser o ka boela oa finyella mefuta e sa tšoaneng ea ho kenya litšepe tsa masapo, ho ntlafatsa phello ea ho buuoa le boleng ba bophelo ba bakuli.

Ho cheselletsa lisebelisoa tsa bongaka tse kenang lipakeng

Lisebelisoa tsa bongaka tse kenellang ke lisebelisoa tsa bongaka tse nepahetseng tse hlokang ho etsoa le ho sebetsa ka nepo. Mechini ea welding ea Laser e ka fihlela welding e nepahetseng haholo ea lisebelisoa tsa bongaka tse kenellang, ho qoba mathata a kang deformation le liphoso tse bakoang ke mekhoa ea khale ea ho tjheseletsa. Ka nako e ts'oanang, mechine ea ho tjheseletsa ea laser e ka boela ea finyella ho cheselletsa mefuta e sa tšoaneng ea lisebelisoa tsa bongaka tse kenang lipakeng, ho ntlafatsa katleho ea ho buoa le polokeho ea mokuli.

Ka bokhutšoanyane, mechini ea welding ea laser e 'nile ea sebelisoa haholo indastering ea lisebelisoa tsa bongaka, e leng se tlisang liphetoho tsa phetoho tlhahisong ea lisebelisoa tsa bongaka. Ha e ntlafatse feela katleho ea tlhahiso le ho fokotsa litšenyehelo tsa tlhahiso, empa hape e ntlafatsa boleng ba sehlahisoa le polokeho. Ka tsoelo-pele e tsoelang pele ea thekenoloji le tlhokahalo e ntseng e eketseha ea likopo nakong e tlang, litebello tsa ts'ebeliso ea mechine ea li-welding tsa laser indastering ea lisebelisoa tsa bongaka le tsona li tla ba tse pharaletseng haholoanyane.

Lintlha tsa Mochini

Lenonyeletso le bohlale la ho tjheseletsa

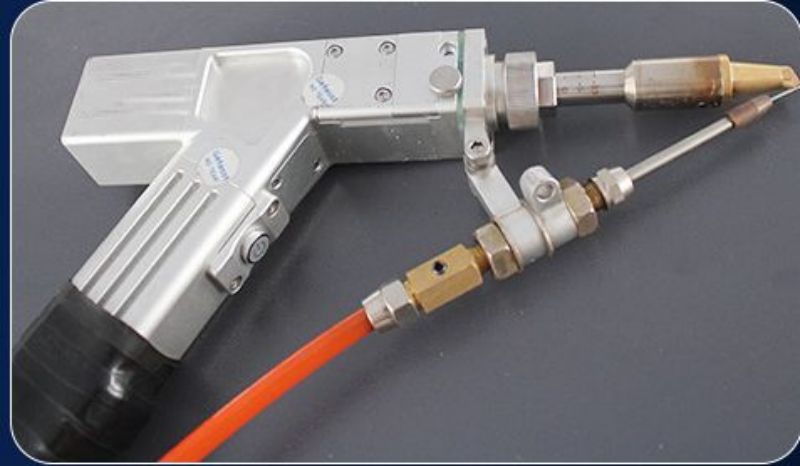

Moloko oa bone oa hlooho ea welding e bohlale e boima ba 0.8KG feela, ts'ebetso ea nako e telele ha e khathale, 'me moralo oa potoloho ea metsi a mabeli o na le phello e ntle ea ho pholile le botsitso bo botle.

Lilense tse sireletsang habeli

Bophelo bo bolelele, ho sireletsa seipone se lebisang tlhokomelo le hlooho ea QBH ka katleho, ho fokotsa ka katleho tšenyo ea likarolo tse ling tsa hlooho ea welding e bakoang ke ts'ebetso e sa lokelang ha lense ea tšireletso e senyeha.

Konopo ea hlooho ea rona ea welding ea moloko oa bone e sebelisa theknoloji ea ts'ireletso ea anti-accident ho thibela tlhahiso ea laser e bakoang ke ho ama konopo ka phoso, e bolokehileng ho feta ho e sebelisa.

Nozzle ea phepelo ea mohala

Nozzle ea phepelo e amohela moralo o khahlanong le leeme ts'ebetsong ea ts'ebeliso ho thibela ka nepo boleng ba tjheseletsa bo bakoang ke ho kheloha ha terata ea welding.

Sistimi ea Taolo

Mofuta oa V5.2 oa sistimi ea taolo o ka fetola kapele likarolo tse fapaneng tsa mochini mme boemo ba mochini bo ka bonoa ka ho hlaka. Mekhoa ea ts'ebetso e ka boloka lisebelisoa tse ngata tsa data bakeng sa tšebeliso e bonolo le ho tšehetsa phetoho ea lipuo tse ngata

Fiber laser

Mefuta e mengata ea fiber optic excitation

Sesebelisoa sa Optical, bakeng sa bareki ho khetha ka bolokolohi, le bona ba ka khetha mofuta oa laser o tsoang kantle ho naha.

Sesebelisoa sa terata

Hore na sebaka sa welding se chesetsoa joang ke sa bohlokoa haholo ho mochini o fepang terata, mochini oa fepelo oa terata oa k'hamphani ea rona o sebelisa mochini oa stepper ho khanna o matla le o matla, ho qoba phepelo ea terata. Mathata a kang ho fepa ka terata ho sa tsitsang

MOEKETSI MOTS'EANE

| Letšoao la sehlahisoa | HRC Laser | Lebitso la sehlahisoa | Mochini o ts'oarehang oa laser oa letsoho |

| Mokhoa oa ho cheselletsa | Ho tjheseletsa ka letsoho (automatic) | botebo ba ho tjheseletsa | 0.8-10MM |

| Bophara ba welding | 0.5-5MM | Tothusa ho fumana | lebone le lefubedu |

| Khase ea ho cheselletsa | Moea o hatelitsoeng oa Argon Nitrogen (ha ho na metsi) | lebelo la ho tjheseletsa | 1-120MM/S |

| Bolelele ba fiber ea Optical | 10M | Botenya ba poleiti ea welding | 0.3-10MM |

| Mokhoa oa ho pholisa | E pholileng ka metsi | tlhokeho ya matla | 220V/380V 50/60Hz |

| Boholo ba lisebelisoa | 1200*650*1100MM | Boima ba lisebelisoa | 160-220KG |

| Sebopeho sa weld | ho tjheseletsa butt;welding lap;rivet welding;roll tjheseletsa; T tjheseletsa;overlap welding,;welding ka bohale,;etc | ||

| Lisebelisoa tsa ho cheselletsa | Tšepe e sa hloekang, tšepe, tšepe ea carbon, aluminium, motsoako oa aluminium, koporo, lakane e entsoeng ka masenke. | ||

MOHLALA PONTS'O

Ho paka & ho Romela

Mochine o ne o tla kenngoa ka har'a kreiti e tiileng ea lepolanka bakeng sa likepe tsa machaba, tse loketseng lipalangoang tsa leoatle, tsa moea le tse potlakileng.